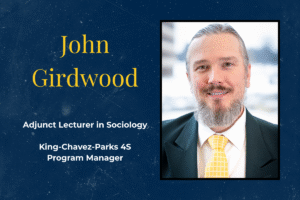

On April 10, 2015, engineering students from EGR 465/466 Senior Design presented their senior projects to a full room of fellow students and university staff, faculty, and administrators, including Dr. Terry Van Allen, Director of the Office of Research and Sponsored Programs, and Chris Waters, Associate Provost and Dean of Undergraduate Studies.

This was the first time that senior engineering students have presented their works to a general campus audience. In the past, presentations have been made to the program’s alumni advisory board.

The event was coordinated by Assoc. Professor Quamrul Mazumder. He defined it as “a comprehensive demonstration of everything [the students] are learning in engineering.” As the students went through their presentations, covering items like project characteristics, design overview, prototype test plans, feedback and redesign details, budget, and testing, the audience could easily see the myriad ways in which these students have been prepared for their future careers in engineering.

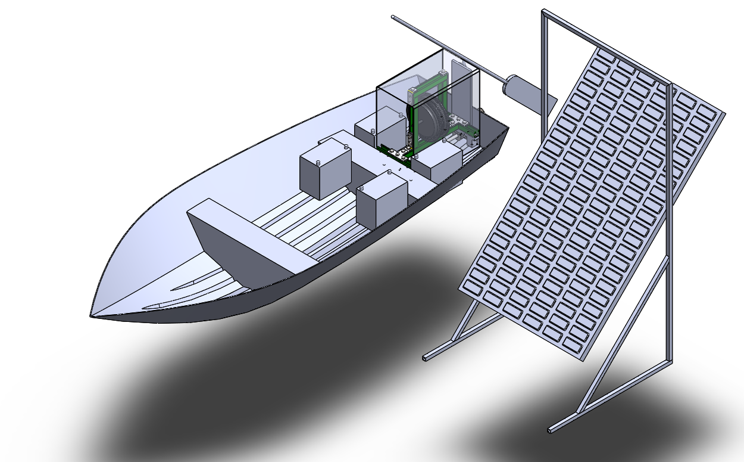

PROJECT ONE: Solar Boat

The first group was made up of students Dan LeBlanc, Frank Hyde, Conner Geml, and Joe Jerisk. Their project was inspired by Solar Splash, “an intercollegiate solar/electric boat regatta” for which students design and build watercraft powered by solar and electric engines while adhering to very specific design parameters.

The UM-Flint students started with an existing fiberglass vessel purchased online, unlike other schools whose students build boats specifically for the competition. During the presentation it was noted their boat “wasn’t perfect, but we made it work.” The group’s biggest challenge was designing the battery, which had to weigh less than 100 lbs., must include a dead man switch, and had to be a lead-acid type. It was a challenge they overcame. Their battery is charged by an on-shore solar panel and powers a pulley-style motor that runs the propeller. The students also faced significant challenges in designing and creating the motor, propeller, shaft, and rudder.

Although the UM-Flint students and their boat won’t be competing at this year’s Solar Splash event, they ran their finished project through several of the event’s trials including straight line speed and maneuverability. Because they were limited by availability of open water, they did not test for endurance of battery life. All members of the group seemed satisfied with their craft’s results as they presented videos of their test runs to the audience.

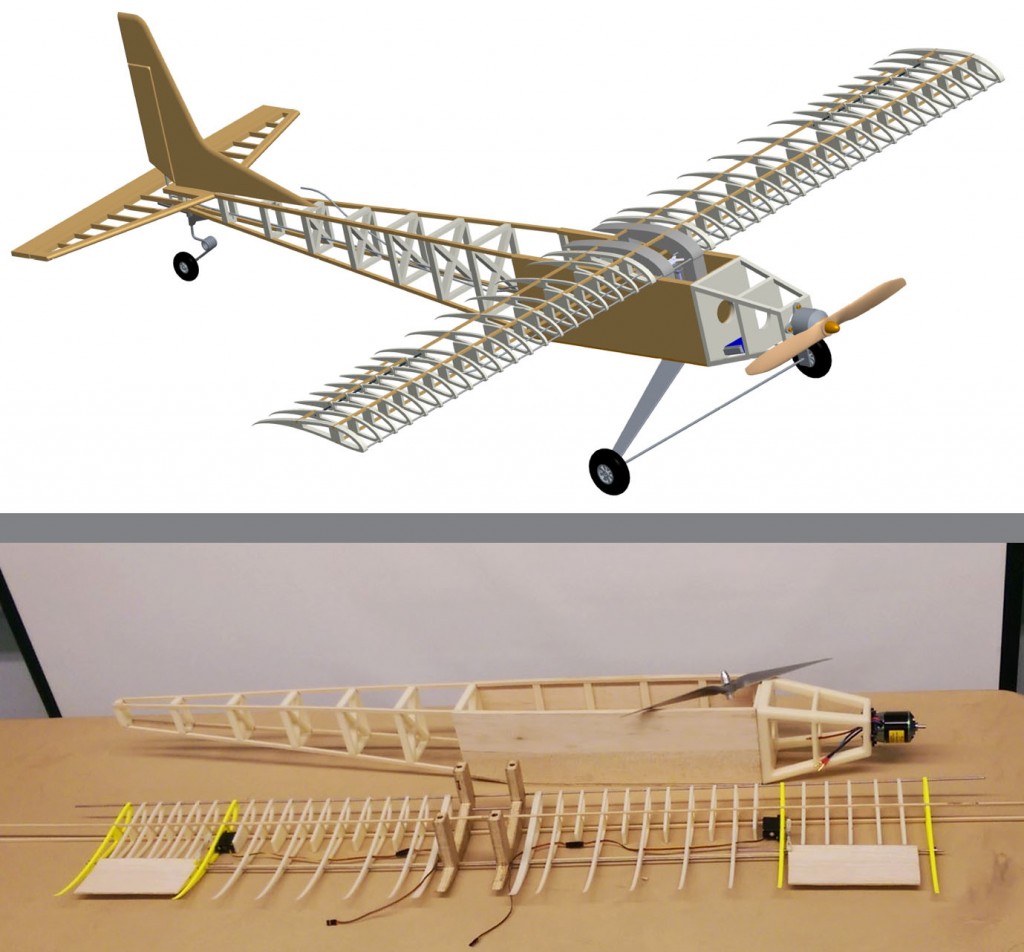

PROJECT TWO: SAE Airplane Design

The second team of the day was made up of Justin Ladd, Connie Lam, Scott Sier, Qijun Tang, and Morgaen Vauter. This team followed the mission of the SAE Aero Design Series which aims to “provide undergraduate and graduate engineering students with a real-life engineering challenge.” Their specific goal was to create an operational and controllable aircraft that did not require special tooling or processes to build and which could be easily repaired should something go wrong during flight. The bigger goal, in line with the SAE Series, was to design a light plane that could carry a relatively heavy load.

The wings, propellers, and tail of their aircraft all underwent stringent design development processes. For example, characteristics for four different wing designs were considered; each design’s weight, lift, stability and control, and manufacturability were rated, with the highest scoring design winning. The conventional wing design won out over a bi-plan, canard, or flying models. A conventional tail and front propeller were each chosen through a similar process. The group utilized the campus’ 3D printer, balsa wood, and mylar to create the plane body.

On flight days, the group recorded the temperature, wind speed and direction, and humidity. The plane was tested both on and off campus, with each short flight giving them input on adjustments and compensations that needed to be made for future tests. Their focus on easy repairs came in handy after several rough landings.

The group closed with some final plans for their plane, including adjusting materials to withstand crashes, more consideration given to the weight the plane should eventually carry, and increasing stability during flight.

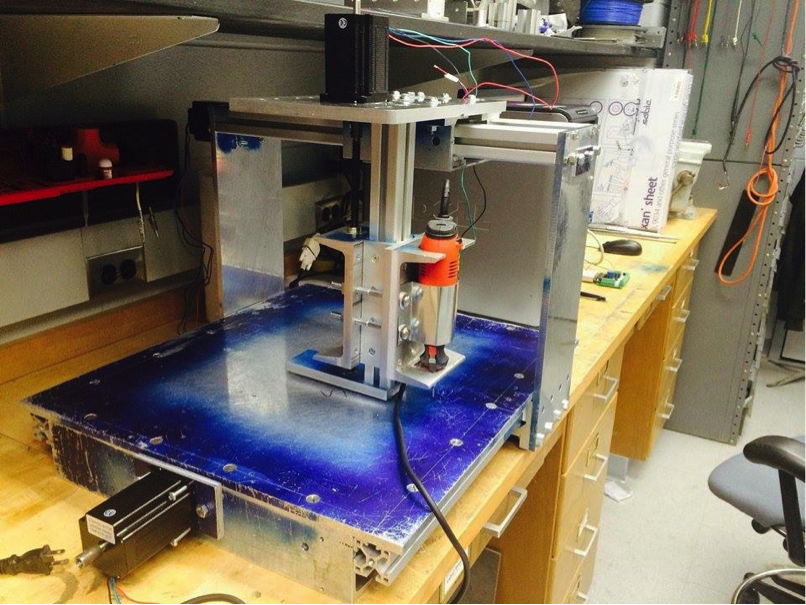

PROJECT THREE: Build a CNC Machine

Group three was made up of students Jin Liu, Zhongehen Du, and Jonathan Arcocha. Their goal was to build an affordable and compact computerized numerical control (CNC) machine that would appeal to hobbyists, universities, students, and others with limited budgets and space. CNC machines use software to direct a tool in an exact way, turning out a consistent product. A common example would be an engraver. Tools used by CNCs can include metal drills, lasers, water jets, plasma cutters, and wire.

After putting in over 450 man hours, the team was able to produce a machine that would match or exceed most current small-scale CNCs on the market in its ability to output pieces in both amount of time spent and size. And, with a budget of less than $700, their price tag was thousands of dollars less than the cheapest small commercial model. Large models, they noted, easily run into six-figure prices.

The students stressed the difficulty and importance of creating a piece that, from the start, is perfectly level and even. Arcocha noted that if the machine itself is off even a fraction of an inch, there is no way it can create pieces that aren’t off as well. Although they completed construction, the team was unable to do much testing as they had an issue with their drivers at the end of the project. However, they seemed eager to continue testing once their new drivers arrive.

PROJECT FOUR: Design and Develop a Food-Grade Latch Clamp

Students Benjamin Jennings and Jianchao Zhong worked together to create a clamp that would be used to hold lids on large containers such as industrial vats or freezers. Working with customer specifications, the pair had to come up with a clamp that suited both size and strength requests, while still maintaining food-grade standards that allow for cleaning and inhibit bacterial growth.

After using equipment on the UM-Flint campus to design, machine, and test the various clamp parts, the two were able to produce a final product that met and even exceeded their original expectations. The students were especially proud of the parts they hand forged and machined. Using still shots, 3-D designs, and video, the pair walked the audience through their project experience, future plans, and testing ideas.

PROJECT FIVE: Robot for Relief

The fifth team included students Kawshik Ahmed, Siwen Zhao, Olugbadebo Adeyemi, and Xiaoy Ma. They were unable to present along with the others, as they were away at an American Society of Mechanical Engineers development conference where they won the student design competition! Their design challenge, Robots for Relief, tasked students with creating a robot able to provide aid when human intervention in a situation is not possible. The robots should be able to do things like deliver water or medical supplies, carry a heavy load, fit in not easily accessible spaces, and traverse uneven or difficult terrain. Read their competition story here.

[youtube]https://www.youtube.com/watch?v=T7W688A33Jc[/youtube]

All of the students presenting reported coming in under budget on their projects, and all expressed thanks to the department and university for the resources they provided. From solar panels, to equipment, to spare parts, the labs and shops at UM-Flint were able to furnish much of what each group needed. It was also obvious that the skills these students have learned during their time in the Engineering program provided them with foundation necessary to produce such advanced senior projects.

For more information on the Engineering Department at UM-Flint, visit their website. For information on student projects, email Dr. Quamrul Mazumder at qmazumde@umflint.edu.